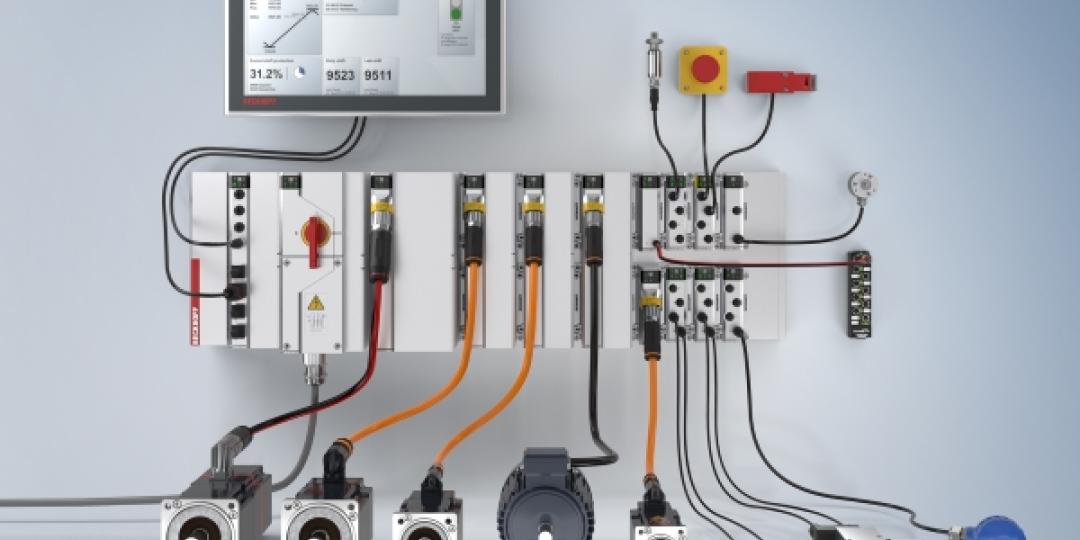

The MX-System from Beckhoff is a flexible, space-optimised and intelligent system solution that can completely replace conventional control cabinets, thereby opening up entirely new possibilities in plant automation. As a modular control cabinet replacement that can also be decentralised on the machine if required, the MX-System saves engineering, assembly, installation as well as maintenance effort. This enables highly efficient processes for the manufacturers and operators of machines and systems – from the planning, setup, and installation of the MX-System through to the maintenance of MX-System-equipped machines.

The basic concept of the MX-System is to standardise the electrical and mechanical interfaces for all electronic and electromechanical components. Implementing this idea results in two interfaces:

The data interface integrates each functional unit into an EtherCAT network and supplies it simultaneously with 24 V DC and, if necessary, also with 48 V DC.

A second interface has been defined as standard for the low-voltage range. These interfaces distribute the mains voltage of up to 530 V AC and a DC voltage of up to 848 V for the drive system. This standardisation allows all functionality traditionally found in a control cabinet to be mapped as a backplane system. Analogous to the interfaces, there are two different backplane types, which have the described interfaces in the form of connectors as essential features. The backplanes feature robust aluminum housings. The combination of backplane and housing is called a baseplate. In addition, there is a full range of function modules from the areas of IPCs, bus couplers, I/O, motion, relays and system power supply. These are simply plugged and screwed onto the baseplate. The combination of a baseplate and function modules results in an IP67-protected automation system that is optimised in terms of space utilisation and can be mounted directly on the machine.

Advantages for engineering

The system architecture of a baseplate combined with function modules results in a modular solution that can be used to solve a wide range of automation tasks. A particular advantage is that the MX-System function modules integrate individual functions, such as line protection for outgoing lines. This facilitates project planning and significantly reduces the number of components. These advantages are evident in the fact that the number of pages in circuit diagrams and parts lists is reduced by up to 80%. Even in the engineering phase, the low installation space requirement of the MX-System creates further advantages because this facilitates simpler coordination between departments, as there is usually no need to design special installation spaces and brackets for the MX-System. Another important aspect is that the MX-System meets the requirements of relevant control cabinet standards and, in contrast to conventional control cabinets, it is also IEC, UL and CSA-compliant, making it a globally standardised solution.

For more information visit https://www.beckhoff.com/en-za/